|

|

Post by stormchaser on Jul 7, 2020 21:37:11 GMT -5

This has been in the works for quite sometime. While I have not purchased any of the parts yet, I will be pulling the trigger shortly. Do you guys approve / and/or offer recommendations based on my hardware choices... Only thing I already have is the rig on air cooling and the coolermaster case that houses it.

I am essentially trying to build a high performance liquid cooling system with a 120mm radiator as the core. I went to AlphaCool and chose their thickest 120mm rad:

This is because the coolermaster case I am using for this build does not have provisions for anything larger than a 120 mm rad

*I promised to switch from air cooling (currently running the MSI Core Frozr XL 120) which holds 5GH on the 9600KF no problem, however, it will get a little loud under heavy CPU load. But I'd prefer to try the greener grass on the otherside so we are moving to liquid cooling:

MORE ON THE CASE I WILL BE USING:

*I like the look and I've owned this case prior so I want another go with it

*It is nearly silent with cladding and sound deadening within (= more heat to deal with)

*As a challenge to see just how much I can get out of a relatively difficult to cool case with a relatively hot running six core CPU at 5GHz

*For fun This is a for fun project and offers purely entertainment value, but make no mistake it will server a very serious purpose and this will not be a walk in the park.

The thicker 120 mm radiator will work with my setup is because the mounting backplate for the rad is set back about 3/4" so this basically equates to more free space between the mounting area (Meaning the width of the 120mm rad can be larger than average) And I'm not afraid to use the angle grinder if needed

Case in question is the Coolermaster Sileo 500 - a relatively quiet case from the factory. This will be my last build on the other case designs, so for me it will be a milestone achievement

Back:

Side with internal view, note 120mm towards the back. That's where the radiator's gonna go.

Alphacool 14180 NexXxoS Monsta 120mm Radiator Water Cooling Radiator

Watercool HEATKILLER IV PRO CPU Water Block, Intel CPU, Pure Copper

800L/H 8W 7V Water Cooling Pump Tank with 4 Meters Pump Head & LED Power Indicator G1/4 Thread Fast Heat Dissipation CPU Cooling System (12cm-Black)

Bitspower G1/4" Temperature Sensor Stop Fitting, Matte Black

PrimoFlex Advanced LRT 3/8in. ID x 1/2in. OD Tubing Bundle (10ft Pack) - Crystal Clear

XSPC G1/4" 5mm Male to Male Fitting, Chrome, 4-Pack

Single front 120mm case fan:

Noctua NF-F12 PWM chromax.Black.swap, Premium Quiet Fan, 4-Pin (120mm, Black)

Dual 120mm radiator fans:

Noctua NF-A12x25 PWM, Premium Quiet Fan, 4-Pin (120mm, Brown)

EKWB EK-Quantum Torque STC-10/13 Compression Fitting for Soft Tubing, 10/13mm (3/8" ID, 1/2" OD), Nickel, 4-Pack

Barrow Pressure Equalizer Stop Plug For PC Liquid Water Cooling Chromed G1/4 Thread

Water Cooling Copper Filter 2 G1/4" Ports for Liquid Cooling System Loop (Silver)

SDTC Tech 6 Pack G1/4" Plug Fitting with O-Ring for PC Water Cooling Systems, Silver

EK-AF Classic Angled 90° - Black Nickel 2 Pack

EKWB EK-Loop Multi Allen Key

EKWB EK-Quantum Torque STC-10/13 Compression Fitting for Soft Tubing, 10/13mm (3/8" ID, 1/2" OD), Nickel

EKWB EK-CryoFuel Concentrate Coolant, 100mL, Navy Blue

2nd Reservoir: (Yes, I will have two reservoirs in the same loop)

This is actually much more than a reservoir to monitor levels. You can attack up to two D5 pumps down the road and install them at the back of said reservoir(see picture). Essentially, I am building redundancy into the system. If the first pump fails or is flat out just a bad performer, or I just don't like it, I can always shift a few lines and acquire some D5 pumps, and have my system back up and running in short order... off the new pump that would then hang from the Alphacool 15167 reservoir. So we have an extra level of protection here, plus, it's another AlphaCool creation and it will take up two 5.25" drive bays, . But for NOW we are starting this component off as a reservoir and nothing more:

Provisions to mount up to two D5 pumps off this secondary reservoir. For now it's just going to be used as a plain old reservoir, that's all. But down the road, we will tinker with it.

What do you think guys? Is this going to be a durable setup so long as everything is done correctly? Any recommendations on other parts or ideas are welcome. I worked with AIO solutions quite a bit but not so much with custom loops. So this will be my first custom loop and I'm very excited to try this out.

|

|

|

|

Post by ShrimpBrime on Jul 7, 2020 22:33:37 GMT -5

Nice choice on the waterblock. Well the entire build actually  |

|

|

|

Post by Mr.Scott on Jul 8, 2020 17:35:38 GMT -5

Not enough rad. It will heatsoak pretty quickly. Rule of thumb is a single 120 for every 100w.

Flow will not help, nor will multiple reservoirs.

And don't tell me that it's only a 95w processor, because it's under rated as hell. It's more like 160w.

|

|

|

|

Post by stormchaser on Jul 10, 2020 13:12:42 GMT -5

Not enough rad. It will heatsoak pretty quickly. Rule of thumb is a single 120 for every 100w. Flow will not help, nor will multiple reservoirs. And don't tell me that it's only a 95w processor, because it's under rated as hell. It's more like 160w. Oh make no mistake, I am well aware of that. Definitely pushing the thermal limit of a 120 mm rad. I've calculated TDP to be about 175 watts at 5 GHz. And under full load, at stock settings, the 9600KF pulls about 125 watts. The 9600K is actually quite efficient, in example, i5-8400 6-core processor is a 65W TDP part with a lower 2.8 GHz base and 4.0 GHz boost clock, but uses more power.

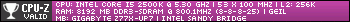

But I did that intentionally. as I want to make it more of a challenge for myself. Didn't want to build yet another run of the mill, cookie cutter water cooled system in a ginormous, alien looking, larger than life gaming case. Plus with that type of build, you can basically set it and forget it -- Where is the fun in that? I want to take this experience to learn as much as possible about the finer details of implementing a competent loop, as I've worked with a number of AIO coolers over the years, but this is my first custom loop. It will most definitely get a 360 mm rad and better case after this little mini challenge has been completed. In short, I'm very curious about just how hard I can push a top tier 120 mm liquid cooling loop and see what kind of margins I get with this particular CPU. The Alphacool radiator I am using is one of the best on the market, and at 80mm thick, provides substantially more surface area than a standard 120 radiator will. I will also be using two high performance 120 mm Noctua radiator fans in a bid to move as much air as possible through the rad. This will be a push / pull configuration and the MSI z390 ACE motherboard that I am using has some great features to help you properly manage and fine tune your custom loop including PWM control for each individual fan. And in point of fact, there are some 120 mm loops on the market that do in fact handle well over 100w. The HP z820 comes to mind. In that case, the stock liquid cooler, also 120 mm, is good for up to 150 watts. And that doesn't even use a full sized 120 mm fan above the rad. This is what I am working with:  With good fans and one of the best copper water blocks on the market, I think I have a fighting chance of making good on 5GHz. I will certainly keep you guys in the loop regarding thermal results. pun intended, lol |

|

|

|

Post by stormchaser on Jul 10, 2020 17:01:39 GMT -5

Not enough rad. It will heatsoak pretty quickly. Rule of thumb is a single 120 for every 100w. Flow will not help, nor will multiple reservoirs. And don't tell me that it's only a 95w processor, because it's under rated as hell. It's more like 160w. Wait, I missed that. Where did you hear the 9600KF pulls 160w? Are you talking stock speeds or when overclocked? |

|

|

|

Post by stormchaser on Jul 13, 2020 22:49:51 GMT -5

Not enough rad. It will heatsoak pretty quickly. Rule of thumb is a single 120 for every 100w. Flow will not help, nor will multiple reservoirs. And don't tell me that it's only a 95w processor, because it's under rated as hell. It's more like 160w. Care to elaborate? In terms of processor voltage? |

|

|

|

Post by stormchaser on Jul 14, 2020 20:10:01 GMT -5

|

|

|

|

Post by MainFramR on Jul 15, 2020 15:38:11 GMT -5

Hi, It will work. The question is how long and how well and at what temperature. A double thick 120mm rad is less efficient than a like 2x120mm radiator by a little bit I'd imagine. That said, Intel CPUs, for quite a few generations now, have blown their TDP out of the water. In the case of a 9600K/KF, they can pull around 175W at 5 GHz using a typical stress test that includes AVX instructions (should always test for the worst IMO). Not sure how well that radiator would do with 175W sustained load. Depends on the fans, etc. It is a low FPI rad (10 FPI I think someone said), so fans with high static pressure aren't really needed as compared with much more dense fin structures. CFM is king here I'd also imagine. www.tomshardware.com/reviews/intel-core-i5-9600k-coffee-lake-cpu,5922-2.html But if you are only testing gaming or non-AVX stress tests it will work just fine. Just depends on what you are doing with it. Anyway, looks neat. I would like to see your results. EDIT: Not sure why, but this forum seems to bork the link after the comma. Copy and paste the whole URL there as the link won't work until it gets fixed.  |

|

|

|

Post by stormchaser on Jul 15, 2020 15:42:33 GMT -5

|

|

|

|

Post by Mr.Scott on Jul 15, 2020 15:54:39 GMT -5

EDIT: Not sure why, but this forum seems to bork the link after the comma. Copy and paste the whole URL there as the link won't work until it gets fixed.  Interesting. I cannot fix it either. It is a Proboards thing. Ticket submitted.  |

|

|

|

Post by stormchaser on Jul 15, 2020 16:39:31 GMT -5

Hi, It will work. The question is how long and how well and at what temperature. A double thick 120mm rad is less efficient than a like 2x120mm radiator by a little bit I'd imagine. That said, Intel CPUs, for quite a few generations now, have blown their TDP out of the water. In the case of a 9600K/KF, they can pull around 175W at 5 GHz using a typical stress test that includes AVX instructions (should always test for the worst IMO). Not sure how well that radiator would do with 175W sustained load. Depends on the fans, etc. It is a low FPI rad (10 FPI I think someone said), so fans with high static pressure aren't really needed as compared with much more dense fin structures. CFM is king here I'd also imagine. www.tomshardware.com/reviews/intel-core-i5-9600k-coffee-lake-cpu,5922-2.html But if you are only testing gaming or non-AVX stress tests it will work just fine. Just depends on what you are doing with it. Anyway, looks neat. I would like to see your results. EDIT: Not sure why, but this forum seems to bork the link after the comma. Copy and paste the whole URL there as the link won't work until it gets fixed.  My goal is going to be passing a 30 minute torture test with prime95 or AIDA64. I am about 90% confident I can hit this mark. I also calculated the max TDP for the 9600KF to be around 175 watts. Care to elaborate a little on FPI? I would assume more FPI typically results in better cooling performance? And yes, this particular radiator has about 10-11 fins per inch and is about 80 mm thick. I have been talking with someone who uses this same 120mm rad to cool an FX9590, which is a 220w CPU from the factory. The CPU is stock but according to his results, the Monsta 120 appears to have no problems keeping the temps under control (with two fans in push/pull) and he has no problems with the CPU thermal throttling either. Granted, I would take that with a grain of salt, but if he is being truthful that's good news for me, as my 9600KF will put out much less than that, even at 5Ghz. There is also a guy on Amazon who left a good review for this little 120mm rad. Apparently, he has an AMD Radeon HD 6990 GPU and AND a 4 core i7 4771 Intel CPU on the same loop and uses only one of these coolers. Granted, it's only an 84w TDP CPU, but still, if he is being truthful, I should have no problems keeping my 9600KF cool. As that video card is capable of pulling upwards of 375 watts at full power, and is known as a hot running card.I also have an option of mounting one of the fans (the pulling fan) in the push/pull configuration, on the outside of the case. Reason I say this is because with a radiator that is 80mm thick, and two fans, it's going to stick out quite a ways into the center of the case. If I have fitment problems I can always cut out the screen and put the "pulling" 120mm fan on the outside to make more room inside the case, as needed. I can also use my angle grinder to cut out the mesh so that we get maximum airflow through both fans and the case. I am also putting a 120mm noctua HD case fan (up to 3000rpm PWM) directly above the water block to actively cool VRMs and memory, in addition to keeping a steady supply of fresh air going across the top of the water block. For this fan, I will have to cut a 120mm x 120mm square out of the left side of the case side cover, and then I am going to use a fine magnetic mesh filter to give it a nice fit and finish when everything is mounted properly. |

|

|

|

Post by stormchaser on Jul 15, 2020 17:15:14 GMT -5

EDIT: Not sure why, but this forum seems to bork the link after the comma. Copy and paste the whole URL there as the link won't work until it gets fixed.  Interesting. I cannot fix it either. It is a Proboards thing. Ticket submitted.  Still no response? Care to elaborate on your other post? I still don't know if you are referring to stock or overclocked TDP relative to the 9600K. You seemed to drop off the map after making that comment. Did you not realize that there are in fact some 150w TDP 120mm liquid cooling systems in the wild? Not sure what you take me for, but I can tell you without a doubt no competent over-clocker ever assumes stock TDP when building a suitable cooling system for one of their rigs, so your comment was slightly surprising, seeing as how you know I have been overclocking for a number of years now and that would be a very stupid error to make. I assume by heat soak you mean the loop will eventually become overwhelmed under a sustained high load situation as all the water begins to heat up? To counter this problem I have integrated a large two bay (alphacool) reservoir to add approximately one quart of additional coolant for the loop, although I don't know how much good it will do under sustained high load situations, but I like the fit and finish and I think from an aesthetics perspective, the extra reservoir will look good when said and done. I also have an extra backplate which will allow me to convert the two bay 5.25" reservoir to a pump/reservoir combo with provisions to mount up to two D5 pumps at the back of it (see pics above). And this does give me options later if I want to move away from the original pump and reservoir combo. Just mount the new D5 motor, switch a few of the lines around, refill the loop and I will be back in business with a different motor/pump to test out. Even of the original pump/reservoir works out okay, I will still be proceeding with this out of curiosity to see how a different pump/motor affects the performance/nvh of the loop. You may simply be not understanding my true motivations here: I am intentionally making this challenging for myself. I'm not building "the best" cooling system for my given hardware. I could easily do that as well and it would be boring. Matter of fact, I could even fit a 360mm rad in this case if I did it right. No, the point is to push my hardware a little bit and lower my margins for error to see if it can be done with just a single 120 mm cooler and make the entire project more challenging. This will not be a waste of hardware or $$$, either. Because the actual components of the loop will be used long after this project is complete to cool a much higher core count CPU. At that point I will likely upgrade to 280mm rad and a better designed case as I see fit, when the time calls for it. But for now, my heart is set on just how much performance I can extract from a very small 120mm cooling system. |

|

|

|

Post by MainFramR on Jul 15, 2020 17:42:03 GMT -5

Hi, Here is information on FPI. www.ekwb.com/blog/radiators-part-1-thickness-fpi/#:~:text=FPI%20stands%20for%20%E2%80%9CFins%20Per,a%20length%20of%20one%20inch. But yes, generally, the more fpi the better the cooling can be as there is more surface area for the beat to get out of the radiator. The more fpi, the harder it is to push air through it. But there are several other factors that go into it. I'm sure it will work. We've seen a slim 120mm radiator cool a 500w load (amd r9 295x2) at 90C so I wouldn't call it too much of a challenge with a 80mm thick radiator. Just depends on how hot you want to run your water. 30 minutes is nothing, especially if you are adding a quart of water in a reservoir. It will only delay time it takes to saturate/ heat soak. The capacity remains the same. I recall other forums me toning to test for at least an hour to make sure things are at an equilibrium. But of course you can test any way you choose and call it a win. The other big thing here is the tiny die in the cpu you want to cool. It isnt so much the capacity that need to be cooled so much as it is getting the heat out of the die. I was literally a couple C better on a 9900k when I jumped from a 2x120mm to 3x120mm. Looking forward to the results. |

|

|

|

Post by osmiumoc on Jul 15, 2020 19:44:33 GMT -5

I assume by heat soak you mean the loop will eventually become overwhelmed under a sustained high load situation as all the water begins to heat up? To counter this problem I have integrated a large two bay (alphacool) reservoir to add approximately one quart of additional coolant for the loop, although I don't know how much good it will do under sustained high load situations, but I like the fit and finish and I think from an aesthetics perspective, the extra reservoir will look good when said and done. I also have an extra backplate which will allow me to convert the two bay 5.25" reservoir to a pump/reservoir combo with provisions to mount up to two D5 pumps at the back of it (see pics above). I'd like to give some cents too, I'm a big water enthusiast. Heat soak means that the surface area of the fins in the radiator will not provide enough raw heat-transfer rate at small delta Ts above ambient to make the loop settle. It means that after powering on, your loop will be on ambient but will rise and rise and rise in temp until finally that delta T to your airflow will be large enough to exchange X amount of TDP your CPU is putting out. This will then be your final stable temperature the system will settle on. Usually you want overkill radiator fin area to keep that settle point as close to ambient temps as possible. With a single 120mm radiator it might be that your loop will reach e.g. 45°C water temp in 20°C ambient. So your coolant (=your waterblock) will be 45°C. Not ideal. If you take a 360 rad instead you could potentially overcome the thermal output of the CPU much sooner and settle at 28°C water in a 20°C ambient. So your CPU will run 17°C cooler. With the 120 rad, even the thick one, you COULD end up with no improvement compared to an aircooler. COULD, I have no idea how it will perform and I'm really looking forward to the result. With strong airflow you can also combat heat-soak to a certain degree, if you get an industrial fan on the radiator e.g.. And if you don't run benchmarks that go for 30 minutes or longer, you may never even see the system reach that point as you will never give it enough time to fully soak. Adding more coolant will NOT help you. Another reservoir will just slow down the process of soaking, but since the reservoir will barely dissipate any heat it will not help you get a lower temp settle point. And same goes to pump speed and power. A single D5 has enough flow for such a small loop with only one radiator and one component. Adding more will not do anything as you will see with your temperature sensors. The water is moving so quickly that you will have an even temperature across the whole loop. You really need to drop the flowrate down to a trickle in order to see some variation in loop temperature OR you need a very big loop. I had an SR-2 watercooled with both CPUs, VRMs, Chipset and a GPU in the loop. Two internal and one external radiator on top. This was large enough that I could see the water moving around by just the temperature sensor, since temperature climbed up in small 'steps' of a couple degrees each time. Each step represented the water doing one full pass through. |

|

|

|

Post by stormchaser on Jul 18, 2020 22:48:59 GMT -5

I assume by heat soak you mean the loop will eventually become overwhelmed under a sustained high load situation as all the water begins to heat up? To counter this problem I have integrated a large two bay (alphacool) reservoir to add approximately one quart of additional coolant for the loop, although I don't know how much good it will do under sustained high load situations, but I like the fit and finish and I think from an aesthetics perspective, the extra reservoir will look good when said and done. I also have an extra backplate which will allow me to convert the two bay 5.25" reservoir to a pump/reservoir combo with provisions to mount up to two D5 pumps at the back of it (see pics above). I'd like to give some cents too, I'm a big water enthusiast. Heat soak means that the surface area of the fins in the radiator will not provide enough raw heat-transfer rate at small delta Ts above ambient to make the loop settle. It means that after powering on, your loop will be on ambient but will rise and rise and rise in temp until finally that delta T to your airflow will be large enough to exchange X amount of TDP your CPU is putting out. This will then be your final stable temperature the system will settle on. Usually you want overkill radiator fin area to keep that settle point as close to ambient temps as possible. With a single 120mm radiator it might be that your loop will reach e.g. 45°C water temp in 20°C ambient. So your coolant (=your waterblock) will be 45°C. Not ideal. If you take a 360 rad instead you could potentially overcome the thermal output of the CPU much sooner and settle at 28°C water in a 20°C ambient. So your CPU will run 17°C cooler. With the 120 rad, even the thick one, you COULD end up with no improvement compared to an aircooler. COULD, I have no idea how it will perform and I'm really looking forward to the result. With strong airflow you can also combat heat-soak to a certain degree, if you get an industrial fan on the radiator e.g.. And if you don't run benchmarks that go for 30 minutes or longer, you may never even see the system reach that point as you will never give it enough time to fully soak. Adding more coolant will NOT help you. Another reservoir will just slow down the process of soaking, but since the reservoir will barely dissipate any heat it will not help you get a lower temp settle point. And same goes to pump speed and power. A single D5 has enough flow for such a small loop with only one radiator and one component. Adding more will not do anything as you will see with your temperature sensors. The water is moving so quickly that you will have an even temperature across the whole loop. You really need to drop the flowrate down to a trickle in order to see some variation in loop temperature OR you need a very big loop. I had an SR-2 watercooled with both CPUs, VRMs, Chipset and a GPU in the loop. Two internal and one external radiator on top. This was large enough that I could see the water moving around by just the temperature sensor, since temperature climbed up in small 'steps' of a couple degrees each time. Each step represented the water doing one full pass through. Okay thanks for the tips. The 2nd Alphacool reservoir arrived today. This is a massive reservoir that takes two 5.25" drive bays and is about twice the capacity of the Alphacool pump/reservoir combo listed earlier in the thread, at about one quart. Not familiar with the technology, so forgive me if this question is way off base, but would something like a TEC cooler be a "theoretical" possibility in this loop? I.e. A type of "supplemental cooling" for the reservoir portion of the loop.... I'm just looking for ways to maximize the benefit of having a large reservoir with increased coolant volume. Sorry if some of my questions are off base, I've worked plenty with AIOs, but this will be my first custom loop. And well aware that some of the top tier air coolers on the market will exceed the average heat dissipation of some single 120 mm radiators. The rig originally had an MSI Core Frozr XL, a 120 mm air cooler with 8 heat-pipes and two 120mm fans, that was stable at 5.0Ghz. Then again, there are also some 120 mm coolers in the wild that meet or exceed 150 w TDP. So this project is dual purpose - and while intended to meet some specific performance goals will also be built for certain aesthetics that only a water cooler can bring to the table. I will also move to a full one hour torture test as a final goal. EDIT: I purchased the 2nd Alphacool radiator for about $20, couldn't pass up the deal.              |

|

|

|

Post by stormchaser on Jul 19, 2020 0:18:53 GMT -5

Has anyone used water wetter in a PC loop? While originally designed for automotive applications, it seems like the same principle could be carried over to a PC liquid cooling system?

|

|

|

|

Post by Macsbeach98 on Jul 19, 2020 5:15:19 GMT -5

People have been putting water wetter in for over 10 years

|

|

|

|

Post by osmiumoc on Jul 19, 2020 7:42:27 GMT -5

Not familiar with the technology, so forgive me if this question is way off base, but would something like a TEC cooler be a "theoretical" possibility in this loop? I.e. A type of "supplemental cooling" for the reservoir portion of the loop.... I'm just looking for ways to maximize the benefit of having a large reservoir with increased coolant volume. Sorry if some of my questions are off base, I've worked plenty with AIOs, but this will be my first custom loop. Depends how you set it up. Your TEC will have a warm side that needs to be properly separated from your radiator airflow. Otherwise you will heat up the water with the dissipated heat from the TEC and kill any possible benefit. I have no idea if the TEC would help, in theory it could. Question is if that is in a noticable range. Best thing you could do is have the TEC cool down something like a CPU waterblock and add this to the loop. It would drain some heat out of the system (if the hot side of the TEC is thermally insulated from the loop). If you stick it to the side of a reservoir I don't think you'll see any benefits as the plastic/acrylic will not transfer heat very well. And you might have to worry about condensation on the cold side of the TEC. Still you can give it a try and see if temps change but maybe don't permanently install it yet. Using a TEC as a waterchiller is very inefficient I think. And if you reach the point where you cool the water down below the temperature of the radiators airflow, you will warm it right back up going through the radiator. Which is why you usually don't have radiators in setups with a chiller (you could still use radiators with chilled water in them to cool down the air inside a case e.g.). |

|

|

|

Post by Vinster on Jul 19, 2020 10:31:27 GMT -5

I agree, a TEC would not transfer through plastic very well if at all. You would need a metal surface. You could attach the TEC if small enough to the side of the RADs, but then you would need a lot of them and then a much larger power supply so the gains would differ to the cost of the system ShrimpBrime is the TEC expert in this group. He's done more with them and would be able to comment.

Vin

|

|

|

|

Post by stormchaser on Jul 19, 2020 12:22:18 GMT -5

|

|

|

|

Post by ShrimpBrime on Jul 19, 2020 14:33:03 GMT -5

I agree, a TEC would not transfer through plastic very well if at all. You would need a metal surface. You could attach the TEC if small enough to the side of the RADs, but then you would need a lot of them and then a much larger power supply so the gains would differ to the cost of the system ShrimpBrime is the TEC expert in this group. He's done more with them and would be able to comment.

Vin

Chilling a loop with a Tec is very difficult. You need two water loops to do it right. If air cooling TECs, you'll chill a single water loop, but with a higher delta than running 2 water loops. Right now With pretty much any Ryzen 65w Cpu, you can direct TEC the Cpu would be the best approach with a loop on the Tec. For Intel, the heat output is too great for direct die TEC cooling and why nobody does it. The basic understanding that a TEC from hot to cold side difference is about 30c. If your Cpu was 100w of BTU output, you want at least double the chilling. When cooling a water loop to cool a cpu, you need about 8-10 times the amount of chilling. You are cooling the liquid. Depending on the amount of liquid, that can turn into a lot of surface area to chill. Power requirements to actually run the TEC properly, you want a 15v power supply. Running it on a regular PSU power supply is super risky. This is the main reason why I never implemented TEC into a daily rig. For this set up, stormy has, I'd say for chilling his water loop, probably about 800w of TEC power would do it, if not a great deal more depending on lots and lots of variables. |

|

|

|

Post by stormchaser on Jul 19, 2020 20:28:53 GMT -5

|

|

|

|

Post by osmiumoc on Jul 19, 2020 21:37:39 GMT -5

You can mount the radiator upside down no problem. Any orientation works, just put your ear close to it after filling the loop and bleeding the air out. If you hear any splashing inside it means there is some air trapped and you need to give it a gentle shake or turn it upside down. (Remember to close/seal your reservoir when turning it on its head, it forgot that once and it was not fun  ) Looks good so far, I love the look of drive-bay reservoirs. |

|

|

|

Post by stormchaser on Jul 19, 2020 21:59:00 GMT -5

Couple problems. First, the radiator can only be mounted upside down (as osmiumoc confirmed, this is okay) It's the only way it can work, because any other position and it's either interfering with the PSU or the case cover. I don't want to butcher the case cover if at all possible. Hard to tell from the pictures, but with the radiator upside down the drain port (which is now at the top) is blocked by the PSU fan. So if I want to drain the loop I will have to take it apart first. I am assuming I don't need the drain port for actual coolant line routing? In other words, I can simply connect the two water lines at the base at opposite sides of the rad to complete the loop and simply leave the drain port plugged? Second problem is that with a push/pull configuration the entire apparatus sticks out ALOT, just about to the center of the water block (see pics), so my return line off the waterblock is slightly blocked by the first cooling fan. I was thinking I have two ways to solve this. First, I could modify the front cooling fan with a large drill bit, so I can run the line straight up from the waterblock without fan interference. I just feel like it's not clean this way, so I will avoid doing this if at all possible. And no, rotating the waterblock will not help. Any suggestions? The other thing I was thinking was mounting the pulling fan to the outside of the case, which will give me enough room to run both water cooling lines straight up and out of the water block. This is better, however, it presents its own challenges. I will have to drill new holes in the case in order to get the radiator to bolt directly to it, then I can connect the outer fan from outside the case. I suppose I can simply test thermals with a single fan at first and see if that is sufficient. See pics here:          |

|

|

|

Post by Vinster on Jul 19, 2020 23:16:14 GMT -5

why would you have to drill the case for the rad? Isn't the fan screw holding it anyway? just the screws would go though the fan, then case then in the rad. you just have to make sure the screws are the correct lengths to not dig in the rad.

Vin

|

|

|

|

Post by stormchaser on Jul 20, 2020 0:03:15 GMT -5

why would you have to drill the case for the rad? Isn't the fan screw holding it anyway? just the screws would go though the fan, then case then in the rad. you just have to make sure the screws are the correct lengths to not dig in the rad. Vin The footprint of the radiator, while having the same 120 mm spacing, will not work without drilling because of physical contact between the top of the rad against the case. So I can get it pretty close, but due to physical contact I cannot get it to line up perfectly. I will sleep on it and see what we can come up with tomorrow. |

|

|

|

Post by MainFramR on Jul 20, 2020 7:48:03 GMT -5

Maybe it is just me, but I call in/out ports down on a radiator the right way. If the barbs are up top, that is where the air goes... and your tubing is right there. Generally, you would always want to install a radiator with the barbs down so the air stays away from them. It isn't a huge issue, I've mounted rads with the barbs up top before, but just saying the right way is barbs down in the first place last I understood things. As far as your issue of this sticking into the middle of your case, always measure first! It is possible to know going into it what you just ran across. To resolve the issue, you can use a 45 or 90-degree fitting(s) to route it past/around and use the holes on the bottom of the radiator so you don't need to make as tight of a turn. That top port on the rad is for getting air out and/or filling the loop. Sure you can drain from it when it is upside down, but... it's for bleeding air and filling according to Alphacool. I'd also clean up those cables if possible. The chassis looks a bit basic/old, not sure if there is space between the chassis and motherboard panel, but that is where they should all go. This will give you more airflow in front and clean up the rats nest of cables from a non modular PSU.  |

|

|

|

Post by osmiumoc on Jul 20, 2020 8:21:48 GMT -5

Maybe it is just me, but I call in/out ports down on a radiator the right way. If the barbs are up top, that is where the air goes... and your tubing is right there. Generally, you would always want to install a radiator with the barbs down so the air stays away from them. It isn't a huge issue, I've mounted rads with the barbs up top before, but just saying the right way is barbs down in the first place last I understood things. As far as your issue of this sticking into the middle of your case, always measure first! It is possible to know going into it what you just ran across. To resolve the issue, you can use a 45 or 90-degree fitting(s) to route it past/around and use the holes on the bottom of the radiator so you don't need to make as tight of a turn. That top port on the rad is for getting air out and/or filling the loop. Sure you can drain from it when it is upside down, but... it's for bleeding air and filling according to Alphacool. I'd also clean up those cables if possible. The chassis looks a bit basic/old, not sure if there is space between the chassis and motherboard panel, but that is where they should all go. This will give you more airflow in front and clean up the rats nest of cables from a non modular PSU.  No you want the air in the tubes so it goes to your reservoir and bleeds out. Otherwise you get the air trapped in the rad and air-in-rad = less heat transfer and worse performance. Its only the other way around for AiO units as they have no reservoir and the air would go into the pump. I would try to get that fan mounted on the outside. As for the blue plug, you need to cover it with a real plug like MainFramR mentioned. There are caps with threads and an O-ring on them. The blue rubber is a potential leak hazard. And you can just ignore those drain/fill plugs on radiators, I never used those. If you fill you can do that in your reservoir. It has the fill-port right on the front. For draining you need to check where the lowest point of your loop will be. Judging from the pictures its probably the radiators in/out ports. So for draining you will grab a bucket, slightly tilt the case over the bucket and unplug the tube from the radiator. Even simpler, with flexible tubing and if you leave enough spare length on the tubes, you can detach the radiator for draining from it. |

|

|

|

Post by stormchaser on Jul 20, 2020 12:29:42 GMT -5

Maybe it is just me, but I call in/out ports down on a radiator the right way. If the barbs are up top, that is where the air goes... and your tubing is right there. Generally, you would always want to install a radiator with the barbs down so the air stays away from them. It isn't a huge issue, I've mounted rads with the barbs up top before, but just saying the right way is barbs down in the first place last I understood things. As far as your issue of this sticking into the middle of your case, always measure first! It is possible to know going into it what you just ran across. To resolve the issue, you can use a 45 or 90-degree fitting(s) to route it past/around and use the holes on the bottom of the radiator so you don't need to make as tight of a turn. That top port on the rad is for getting air out and/or filling the loop. Sure you can drain from it when it is upside down, but... it's for bleeding air and filling according to Alphacool. I'd also clean up those cables if possible. The chassis looks a bit basic/old, not sure if there is space between the chassis and motherboard panel, but that is where they should all go. This will give you more airflow in front and clean up the rats nest of cables from a non modular PSU.  Well yeah, the cables are like that because I was mocking up the hardware first to assure best fitment  Generally, how it works, is that you do that first, and THEN you lock everything in place when ready. So the cables will be managed when the time comes. The case is one of my favorites and allows one to build a whisper quiet PC. I actually like the no frills, brushed aluminum finish, including it's simplistic layout and unsuspecting style. Plus, I've wanted to use it in a sleeper build for years now. I am contemplating testing the system with just one radiator fan to see if that's enough... but most likely I will be mounting the 2nd fan on the outside of the case, as that seems to be the best solution coming to mind at the moment and will offer the best performance. This will also give me more room to mount the top 120 mm fan that will be attached to the side cover, and I can position it nearly directly over the waterblock VRMs and memory. I did take measurements and recognized the potential for clearance issues between the waterblock and rad... and I did purchase some 90* fittings for this purpose exactly. I also thought in all likelihood, I may have to mount one of the fans outside the case. |

|

|

|

Post by stormchaser on Jul 20, 2020 13:39:58 GMT -5

Maybe it is just me, but I call in/out ports down on a radiator the right way. If the barbs are up top, that is where the air goes... and your tubing is right there. Generally, you would always want to install a radiator with the barbs down so the air stays away from them. It isn't a huge issue, I've mounted rads with the barbs up top before, but just saying the right way is barbs down in the first place last I understood things. As far as your issue of this sticking into the middle of your case, always measure first! It is possible to know going into it what you just ran across. To resolve the issue, you can use a 45 or 90-degree fitting(s) to route it past/around and use the holes on the bottom of the radiator so you don't need to make as tight of a turn. That top port on the rad is for getting air out and/or filling the loop. Sure you can drain from it when it is upside down, but... it's for bleeding air and filling according to Alphacool. I'd also clean up those cables if possible. The chassis looks a bit basic/old, not sure if there is space between the chassis and motherboard panel, but that is where they should all go. This will give you more airflow in front and clean up the rats nest of cables from a non modular PSU.  As for the blue plug, you need to cover it with a real plug like MainFramR mentioned. There are caps with threads and an O-ring on them. The blue rubber is a potential leak hazard. And you can just ignore those drain/fill plugs on radiators, I never used those. If you fill you can do that in your reservoir. It has the fill-port right on the front. For draining you need to check where the lowest point of your loop will be. Judging from the pictures its probably the radiators in/out ports. So for draining you will grab a bucket, slightly tilt the case over the bucket and unplug the tube from the radiator. Even simpler, with flexible tubing and if you leave enough spare length on the tubes, you can detach the radiator for draining from it. Thanks. When I ordered all the parts I picked up some chrome plugs to replace all the rubber plugs and match the theme of the build. Those will be installed shortly. |

|

)

)